Dirk meyer‘s fire - gilding studio

The technology of fire - gilding

Dirk Meyer‘s

FIRE - GILDING STUDIO

registered conservator in

gold and silver smithery

Phone:

00498383 - 922783

Mobile:

00491577-3548950

E - mail:

dirkmeyer (at) fire-gilding.com

Postal address:

Atelier für Feuervergoldung

Dirk Meyer

Neppen 1

D - 88167 Maierhöfen

Germany

copyright by dirk meyer // webdesign phil zinser

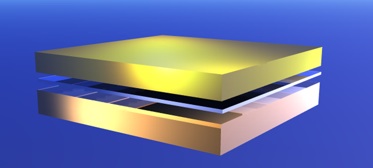

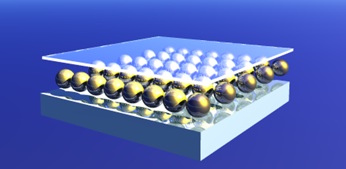

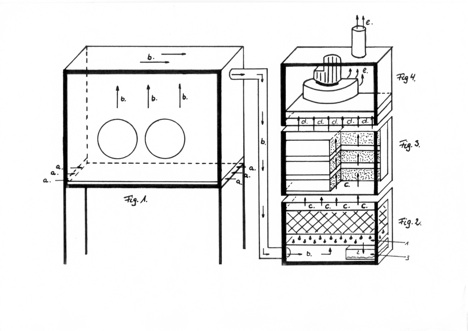

Layout for the implementation of a fire gilding -

Technical condition

Fig. 1 - cubicle

Fig. 3-4 filter/ventilator